SEOUL (Reuters) – South Korea’s factory activity grew at its slowest pace in 13 months in October, led by a contraction in output and softer demand as shortages of chips and supply chain disruption weighed on the sector.

The IHS Markit purchasing managers’ index (PMI) for October fell to 50.2 from 52.4 in September, though managed to stand above the 50-mark threshold that indicates expansion in activity, for a 13th straight month.

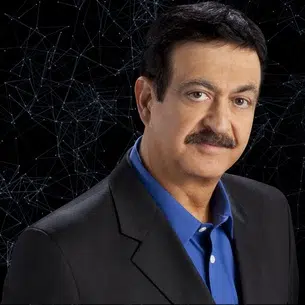

“October data provided proof that ongoing raw material shortages and supply chain issues began to bite in the South Korean manufacturing sector … (pointing) to a broad stagnation in operating conditions,” said Usamah Bhatti, economist at HIS Markit.

Output returned to contraction in just two months, with the sub-index at 46.6, having shrunk at the sharpest rate since July 2020 due to significant shortages of materials, notably semiconductors and other electrical components.

Total new orders and export orders barely grew, with respondents highlighting slowing international demand and difficulties in sourcing freight and container capacity.

Sharp rises in raw material costs amid severe shortages resulted in further rises in costs at South Korean manufacturers, with input prices rising at the sharpest pace in three months.

That led firms to pass higher costs on to clients, also pushing factory gate inflation to a three-month high.

In an effort to protect margins, firms were seen reducing staffing levels for the first time in eight months.

Meanwhile, firms continued to worry about the ongoing shortages and disruptions, with business confidence easing to its weakest level since September 2020.

“This is broadly in line with current IHS Markit estimates for industrial production to grow just 0.2% in 2022 following a 6.2% increase in 2021,” Bhatti said.

(Reporting by Joori Roh; Editing by Sam Holmes)